VEM (Thailand) Co., Ltd.

Categories

Other ManufacturingPackaged Food & BeveragePlastics & Rubber

About Us

Finding the most appropriate plastic manufacturing solution for your project is your goal. As a result, this is what our experienced technical experts & designers made their passion. On the whole, we are in the tooling and plastic injection molding industry for 30 years. Our team of engineers provides you expert insights about your part. Beginning with design and manufacturability all the way to flow analysis. Molding your parts and finding solutions to assemble them, including extensive testing to ensure quality, is nothing new to us! Altogether, we have successfully set up injection molding and assembly lines for many of our partners. At the same time, we improve their existing processes with testing and expertise. Bringing VEM’s known quality to all continents is our goal. Besides that, we ensure successful plastic molding projects and outstanding service everywhere.

Within the last 15 years, we have opened plastic manufacturing companies and tool shops in 5 countries. In the long run, our vision is to not only provide all-in-one solutions all over the globe but to keep shining with our quality and service. For this reason, we value our customer partnerships over everything.

Injection mold making is all about service

injection mold making is what brought us where we are now. Up to the present time, we focus on customer satisfaction as our number one priority. Now that we have established our name in injection tool making, we expand our expertise to other countries and continents.

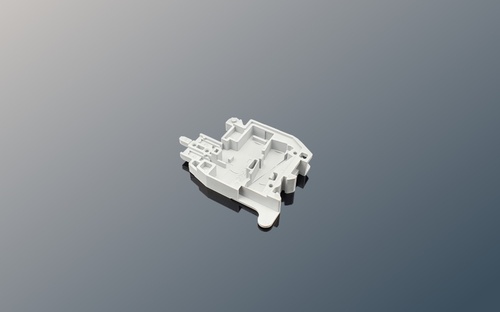

Custom injection mold making

We know the ins and outs of plastic injection molds. So far we have successfully designed, build, and tested over 8000 molds.

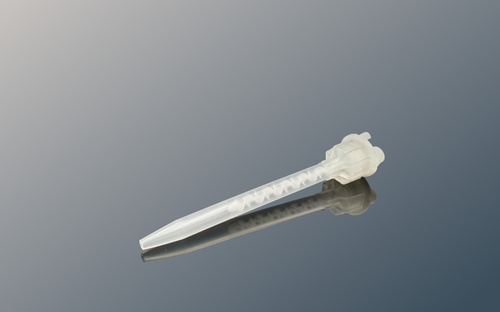

Plastic manufacturing

Plastic injection molding with tools we build in-house is our specialty. Coupled with around 35 injection machines are capable of running large productions. Not to mention the flexibility of our main molding facilities in Thailand, Mexico, and Bulgaria.

Assembly lines & manufacturing solutions

Not only can we produce large amounts of plastic parts. Also, we can utilize the large supplier network that we have built over the years to buy other components. Eventually bringing all parts together in the most efficient and cost-effective way. Even though ensuring consistent quality and documentation.

In addition, we provide a certified cleanroom facility that enables us to set up sensitive medical assembly lines.

Images

Rep/Contact Info

Marc Christopher Weinmann

Managing Director

Porntip Damsanit

Director